New internal testing Department and owner quality control

We have the company’s internal testing department, for advanced tests on the ante-scrolling technologies and for our production in general.

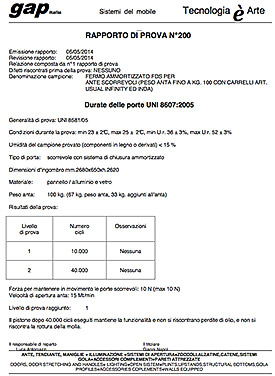

To guarantee the highest quality, we release on request testing documentation.

The tests, the studies of new products and the evolutions that refine the quality are carried out with incessant frequency, to assure the top of the technological quality made in Italy.

Excellence in mechanics, innovation in the study of design and meticulous assembly, make systems for cabinets the top of the range, with results in terms of durability, safety, functionality and elegance never achieved before.

Automated and proprietary quality control procedure

Gap Italia SRL uses a new line of automation entered into the production cycle from 1 July 2018, which controls the formation and packaging of our products and sliding solutions kits.

In addition to increasing the volume of the entire production cycle, the new automated line allows us to guarantee customers certainty – with no margin of error – that all the elements that compose it are inside the kit boxes.

This new procedure eliminates manual controls, increases production speed and guarantees the total quality of Gap Italia to its customers.

The system has been studied and realized on the dynamics of production of Gap Italia, a “tailor made” technology sewn specifically for our company, a decisive step towards the philosophy of “tolerance-zero-errors” that-together with the evolution Constant technological-is today the mission of Gap Italia Srl.